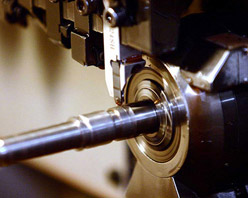

Specializing in the production of small, complex parts and long-cylindrical items – such as crimpers and cylinders, orthopedic instruments, and hydraulic hose ends – Kilgore Manufacturing Company, Inc.’s precision Swiss turning operations offer tight, +/- .0005 of an inch tolerances, and provide parts with a smooth surface finish.

Our Swiss turning processes include, but are not limited to:

- Form Turning

- Taper Turning

- Straight Turning

- External Threading and Internal Threading

- Drilling

- Boring

From one-off prototypes to high-volume manufacturing, our Swiss turning machinery is able to manufacture intricate parts within fast, 3-6 week lead times. Rush services are also available with this service. Contact Kilgore today to learn more about our advanced, ISO-compliant Swiss turning operations.