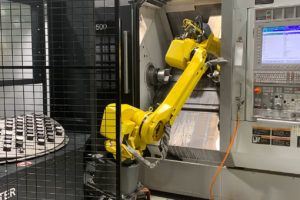

Integrating automation into the production process through the use of robotics helps achieve cost-efficient, consistent machining results. The past few decades have brought significant advances in programmable controllers, motion control capabilities, and CAD software. These powerful technologies have rendered automation more accessible than ever—and their capabilities stand to benefit operations of all sizes.

Automation offers an ideal solution for finishing cuts after the heat treating process. Any operation that requires machines to run for several hours also stands to benefit from automated processes.

Benefits

There are numerous benefits to be found through automating production processes, such as:

- Automated work creates consistent and dependable results no matter the operating conditions.

- Output and productivity improve following the implementation of automation. Users of automated machine tools can anticipate machine uptime more than 85% of the available time.

- Automation eliminates a number of potentially negative variables during production. Controlled processes aren’t subject to time-consuming issues like operator preferences.

- Worker safety regularly improves after automation has been implemented. Worker injuries decline in frequency when problems like part weight and operator fatigue are removed from the production process.

- Automated machining allows for as few human hands to come into contact with the workpiece as possible, which minimizes setup time and lowers the risk of human error.

- Many of the consequences of labor shortages are mitigated.

Regardless of why you opt to automate your machinery, making a forward-thinking decision toward automation now will benefit your organization for years to come. Automation technology is ever-evolving and continues to advance at a rapid pace. Leveraging these tools now better prepares your operation for future demand.